ASU scientists develop innovative twists to DNA nanotechnology

In a new discovery that represents a major step in solving a critical design challenge, Arizona State University Professor Hao Yan has led a research team to produce a wide variety of 2-D and 3-D structures that push the boundaries of the burgeoning field of DNA nanotechnology.

The field of DNA nanotechnology utilizes nature's design rules and the chemical properties of DNA to self-assemble into an increasingly complex menagerie of molecules for biomedical and electronic applications. Some of the Yan lab's accomplishments include building Trojan horse-like structures to improve drug delivery to cancerous cells, electrically conductive gold nanowires, single molecule sensors and programmable molecular robots.

With their bio-inspired architectural works, the group continues to explore the geometrical and physical limits of building at the molecular level.

"People in this field are very interested in making wire frame or mesh structures," said Yan. "We needed to come up with new design principles that allow us to build with more complexity in three dimensions."

In their latest twist to the technology, Yan's team made new 2-D and 3-D objects that look like wire-frame art of spheres as well as molecular tweezers, scissors, a screw, hand fan, and even a spider web.

The Yan lab, which includes ASU Biodesign Institute colleagues Dongran Han, Suchetan Pal, Shuoxing Jiang, Jeanette Nangreave and assistant professor Yan Liu, published their results in the March 22 issue of Science.

The twist in their 'bottom up,' molecular Lego design strategy focuses on a DNA structure called a Holliday junction.

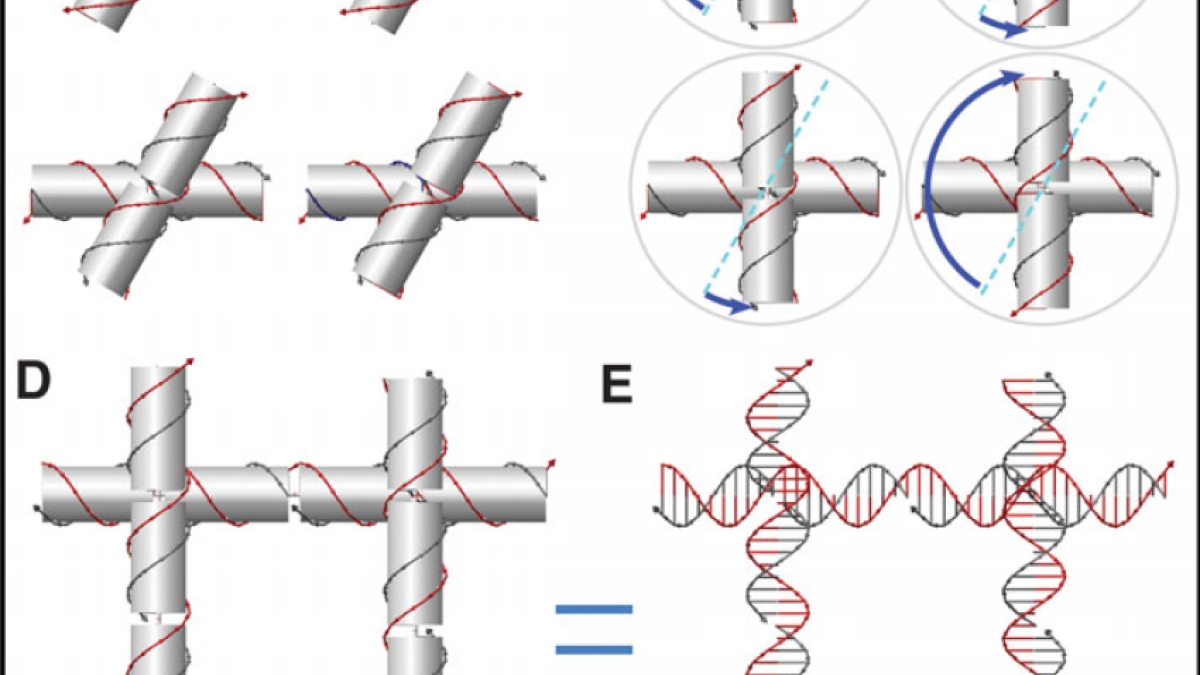

In nature, this cross-shaped, double-stacked DNA structure is like the 4-way traffic stop of genetics – where 2 separate DNA helices temporality meet to exchange genetic information. The Holliday junction is the crossroads responsible for the diversity of life on Earth, and ensures that children are given a unique shuffling of traits from a mother and father's DNA.

In nature, the Holliday junction twists the double-stacked strands of DNA at an angle of about 60-degrees, which is perfect for swapping genes but sometimes frustrating for DNA nanotechnology scientists, because it limits the design rules of their structures.

"In principal, you can use the scaffold to connect multiple layers horizontally," [which many research teams have utilized since the development of DNA origami by Cal Tech's Paul Rothemund in 2006]. However, when you go in the vertical direction, the polarity of DNA prevents you from making multiple layers," said Yan. "What we needed to do is rotate the angle and force it to connect."

Making the new structures that Yan envisioned required re-engineering the Holliday junction by flipping and rotating around the junction point about half a clock face, or 150 degrees. Such a feat has not been considered in existing designs.

"The initial idea was the hardest part," said Yan. "Your mind doesn't always see the possibilities so you forget about it. We had to break the conceptual barrier that this could happen."

In the new study, by varying the length of the DNA between each Holliday junction, they could force the geometry at the Holliday junctions into an unconventional rearrangement, making the junctions more flexible to build for the first time in the vertical dimension. Yan calls the backyard barbeque grill-shaped structure a DNA Gridiron.

"We were amazed that it worked!" said Yan. "Once we saw that it actually worked, it was relatively easy to implement new designs. Now it seems easy in hindsight. If your mindset is limited by the conventional rules, it's really hard to take the next step. Once you take that step, it becomes so obvious."

The DNA Gridiron designs are programmed into a viral DNA, where a spaghetti-shaped single strand of DNA is spit out and folded together with the help of small 'staple' strands of DNA that help mold the final DNA structure. In a test tube, the mixture is heated, then rapidly cooled, and everything self-assembles and molds into the final shape once cooled. Next, using sophisticated AFM and TEM imaging technology, they are able to examine the shapes and sizes of the final products and determine that they had formed correctly.

This approach has allowed them to build multilayered, 3-D structures and curved objects for new applications.

"Most of our research team is now devoted toward finding new applications for this basic toolkit we are making," said Yan. "There is still a long way to go and a lot of new ideas to explore. We just need to keep talking to biologists, physicists and engineers to understand and meet their needs."

Yan's research is funded by several grants from the National Science Foundation, Office of Naval Research, Army Research Office grant and an Army Research Office MURI award, and an ASU Presidential Strategic Initiative Fund. Hao Yan and Yan Liu are part of the Center for Bio-Inspired Solar Fuel Production, an Energy Frontier Research Center funded by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences.

Hao Yan is the Milton Glick Chair in the Department of Chemistry and Biochemistry and researcher at ASU's Biodesign Institute.